Engineering Excellence in Industrial Processing

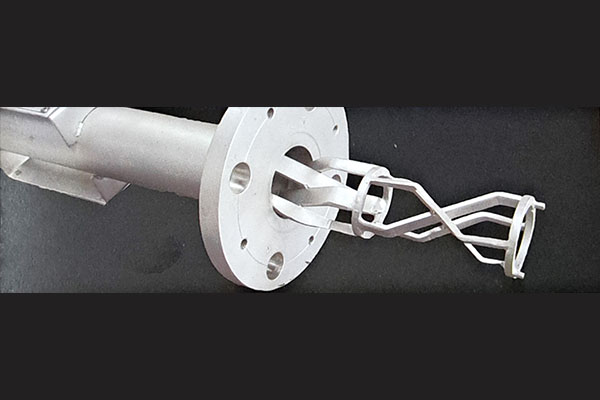

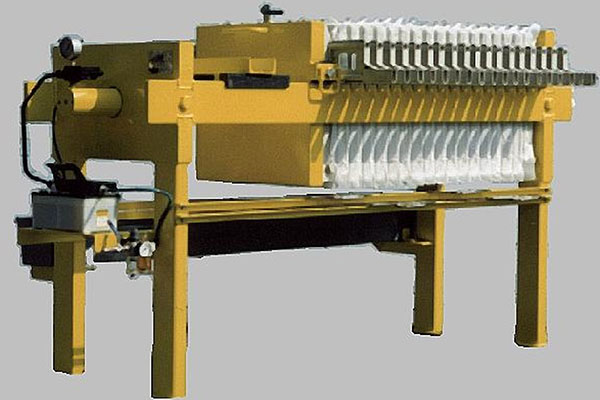

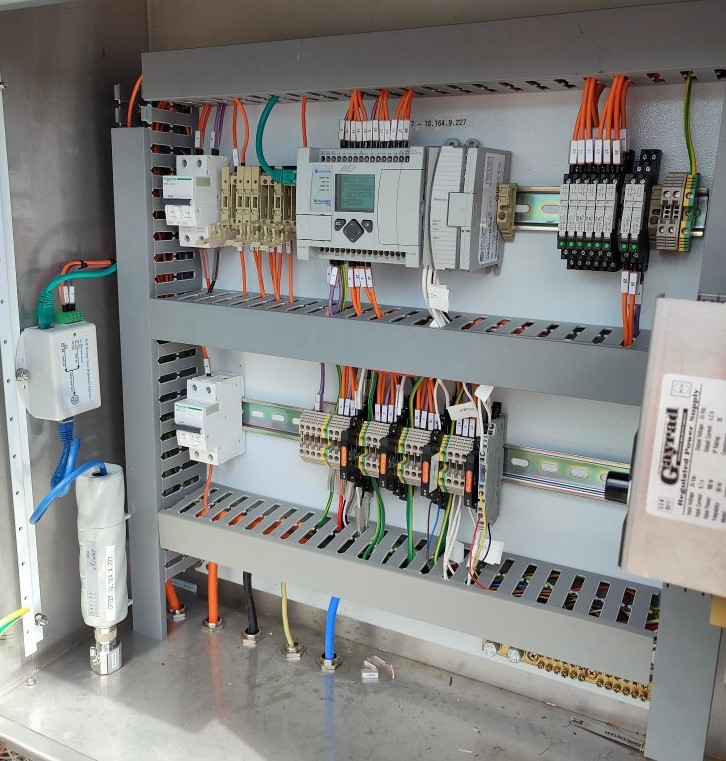

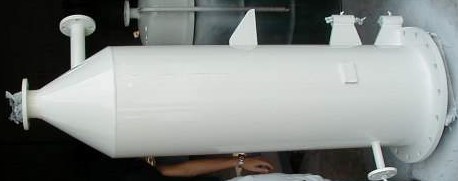

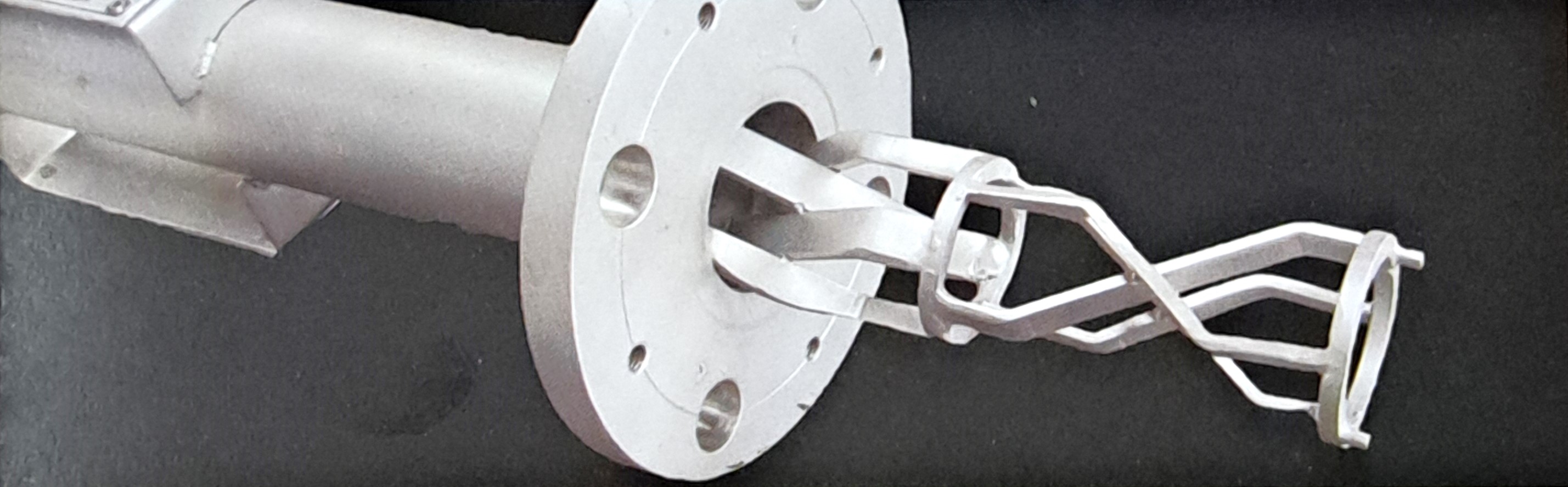

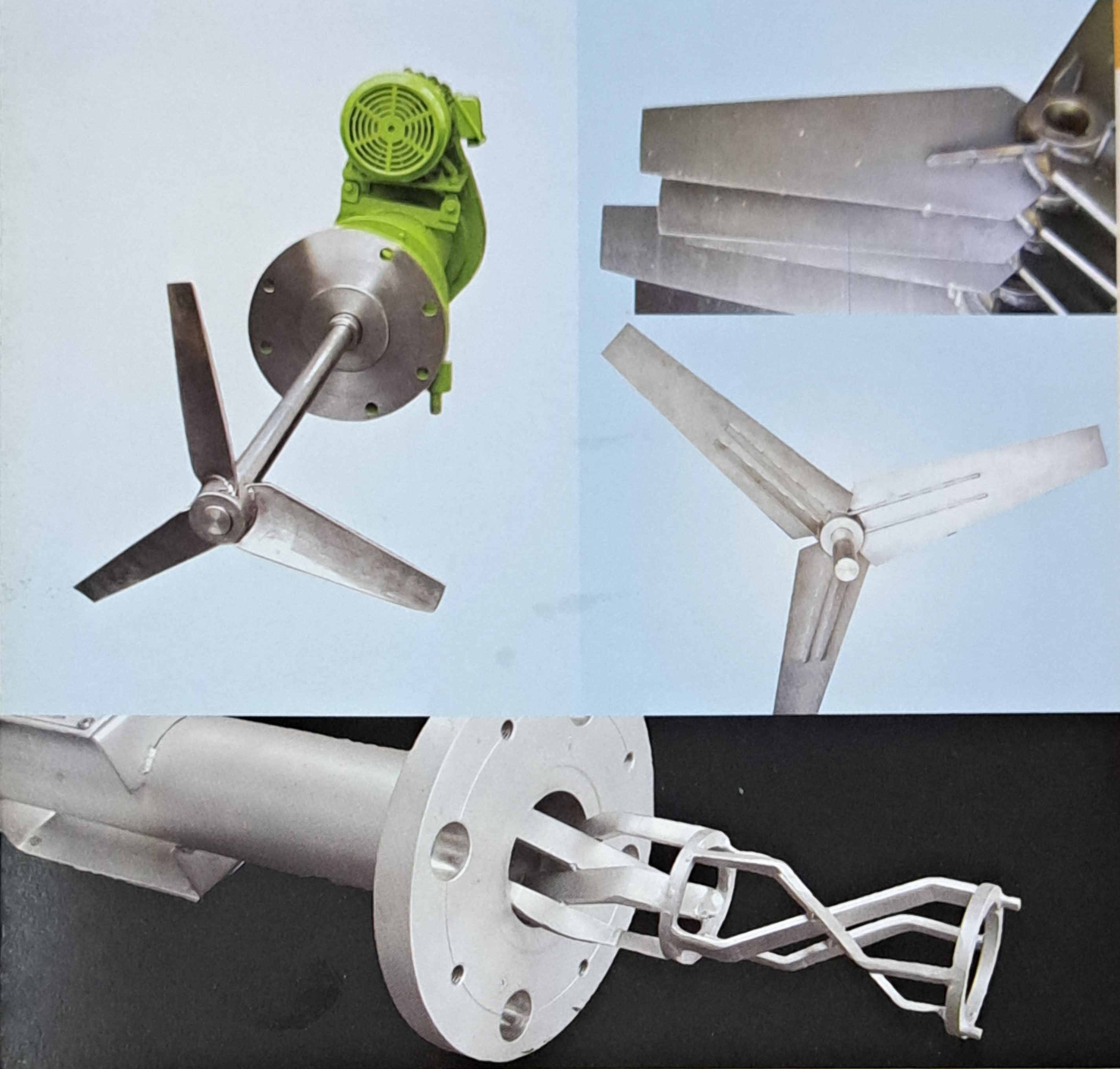

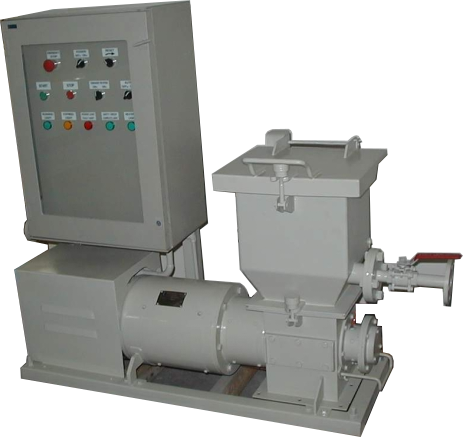

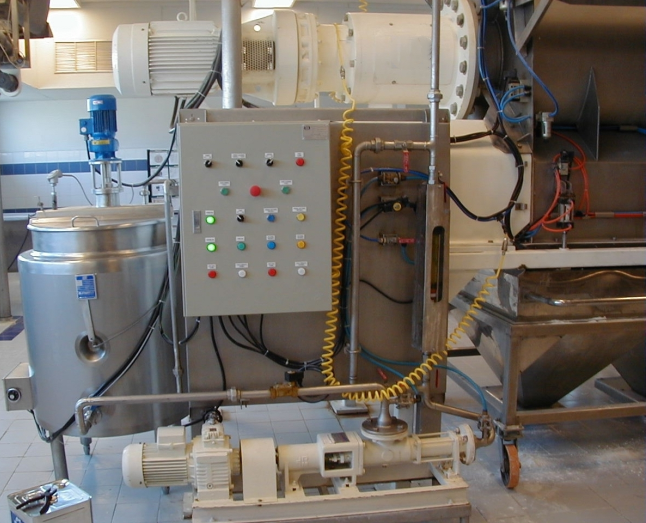

Vivergy Co. Ltd specializes in the installation, management, and servicing of high-quality Industrial Mixers and Pressure Leaf Filters. Since our founding in March 2003, we have delivered hundreds of mixers and filtration systems across seven countries, including Singapore, the US, Australia, New Zealand, Indonesia, and Malaysia.

With a strong presence in the Asia-Pacific region, we leverage decades of engineering expertise to provide tailored machinery solutions across diverse industries.

Let's Talk—Obligation-Free

Whether you need new equipment, maintenance, or operational consultation, Vivergy is here to help. Contact us today to discuss how we can enhance your Industrial Processing Systems.

Read more