Filter Product

Filter Product

Pressure Leaf Filters

Pressure Leaf Filters are highly efficient liquid filtration systems used in a wide range of industrial applications. These systems provide a closed, pressure-resistant solution for filtering liquids with high solid content, ensuring process safety and reliability.

|

Filter Range Brochure (button) |

Pressure Leaf Filter Brochure (button) |

Our Services

At Vivergy, we offer comprehensive services to ensure the optimal performance of your pressure leaf filtration systems. Our services include:

• Installation and Commissioning: Professional setup and testing of pressure leaf filters.

• Maintenance and Repair: Regular servicing and emergency repairs to minimize downtime.

• Filter Leaf Refurbishment: Cleaning, re-meshing, and replacement of worn-out filter leaves.

• Technical Support and Consultation: Expert guidance to optimize your filtration process.

• Spare Parts Supply: Fast and reliable supply of essential spare parts.

Filter Leaves and Spare Parts

Our filter leaves are constructed with multiple layers of stainless-steel wire mesh to provide durability and high efficiency. Available filter mesh options include:

• 60 Mesh (304, 304L, 316, 316L, NSCD, 904L stainless steel)

- Particle retention: 240 microns

• 24 x 110 Dutch Weave (304, 304L, 316, 316L, NSCD, 904L stainless steel)

- Particle retention: 120 microns

• PZ80 Reversed Plain Dutch Weave (3304, 304L, 316, 316L, NSCD, 904L stainless steel)

- Particle Retention: 90 microns

We also provide spare parts such as shafts, spray headers, bearings, O-ring seals, and door gaskets.

How Pressure Leaf Filters Work

Pressure Leaf Filters consist of multiple filter leaves stacked inside a pressure vessel. The filtration cycle starts with precoating, followed by slurry filtration under pressure. Solids accumulate on the filter leaves, forming a cake that is later discharged either dry or wet, depending on the application.

Applications

• Edible Oil Processing

• Winemaking

• Sugar Refining

• Chemical and Pharmaceutical Filtration

• Molten Sulfur Filtration

• Precious Metal Refining

• Bio-diesel Production

Benefits of Pressure Leaf Filters

• High filtration efficiency

• Compact design with a large filtration area

• Fully automated operation reduces labor costs

• Easy maintenance and quick cake discharge

• Robust filter leaves for long service life

• Closed system ensures operational safety

Filter Press

Vivergy also provides a range of filter presses and associated equipment. Vivergy has a pilot scale test filter that can be used to ensure the correct parameters have selected. Vivergy also supplies a range of filter press spare parts.

Filter Presses are designed for the following processes:

• Sterene/Olein Separation of Palm Oil and other vegetable Oils (winterization of vegetable and animal oils)

• Metallic Sludge De-Watering

• Biological Sludge De-Watering, including anaerobic and aerobic digested sludge de-watering

• Tapioca Starch dehydration

• Rice Starch Dehydration.

Bag Filters and Pulse Tube Filters

Vivergy supplies pulse tube filters. These filters are cleaned by pulses and can provide a more economic measure for processes with high

filter bag replacement rates.

Standard features

• Easy access with eye bolts and attached opening tool

• Vessels Designed and built according to ASME Code.

• Precision machined to ensure no leak - Inlet and outlet nozzles strategically located to avoid excess pressure drops and cake disturbances due to flow.

Applications

• Food Polishing Bleached Edible Oil, Sugar Starch Filtration, Activate Carbon

• Chemicals/Plastics Resin Filtration, Activated Silica Filtration, Catalyst Filtration

• Building Material Pigments, Industrial Fibers, Abrasives, Gypsum

Special Options

• Connection Flanges Single Bag Filters, Double Bag Filters. Multi Bag Filters

• Indicators Flow Meters, Pressure Drop Meters

• Material SUS304, SUS316L and Carbon Steel

• Heating Steam Jacketed, Internal Coil

• Special feature Side or Top Entry models in accordance to the application.

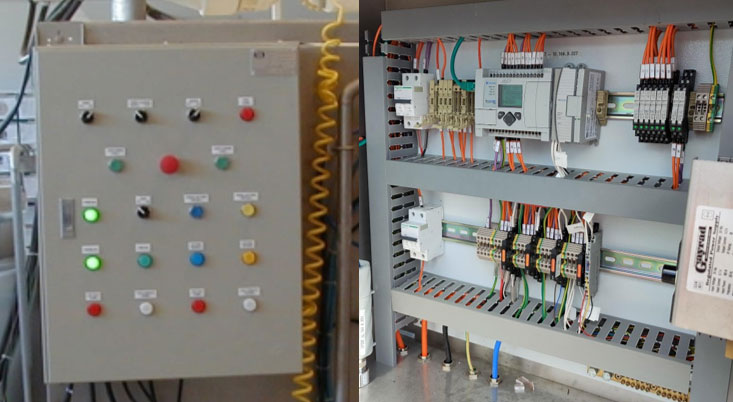

Filtration Control Systems

Discover VIVERGY's range of precision-crafted pressure leaf filters. Our expertly engineered control systems ensure optimal performance for pump feeding and valve control. Whatever your filtration needs, VIVERGY delivers a comprehensive control solution designed for versatility across a variety of applications.

|

Our Services Offered: · Advanced PLC Programming · DCS Systems · SCADA & HMI Development · System Migration · Licensed / Unlicensed Radio Telemetry · Simulated Factory Acceptance Testing

|

· Rockwell Automation · Schneider · Mitsubishi · Siemens · Coolmay · Beckhoff · Pilz · Omron · Miri Technologies · Ignition SCADA · FactoryTalk · Citect SCADA · And More… |

30 April 2025

Viewed 107 times